2nd Gen Camaro Suspension Install Guide

This 2nd Gen Camaro Gets Second Chance Handling with Aldan American Coilovers

By Cam Benty

Photos by Cam Benty and Gary Nelson

Aldan American upgrades for Gen 2 Camaros that really make a difference

While first Generation Camaros/Firebirds may steal all the headlines, the second Generation Camaros/Firebirds that debuted in March 1970 (and continued production through 1981) featured far advanced suspension designs over their first Gen (1967-69) cousins. While both platforms utilize a front subframe suspension, the 2nd Gen suspensions in stock form delivered better tire contact. The steering box is mounted in front of the axle centerline, which is considered a front steer chassis. In addition, wider A-arm mounts and taller spindles allowed for improved negative camber gain while retaining a low roll center height. If all that’s beyond your understanding of suspension tech, the take away is that the 2nd Gen cars offered better at handling than the early cars both straight line and in the corners.

With all these things in its favor, the 2nd Generation Camaro/Firebird responds well to aftermarket upgrades especially the coilover suspension kit offered by Aldan American. As we have learned from our experience with many of their suspension makeovers, Aldan American coilover kits deliver plenty of adjustability via a simple turn of the shock mounted adjustment knob, a wide array of differently rated coil springs along with easy ride height adjustments (to lower that critical vehicle roll center point). It’s all good as they say.

2nd Gen Camaro Coilover Install:

Our test vehicle was a 1970 Camaro that has already been enhanced with a host of drivetrain and suspension upgrades. While most of our Aldan American upgrade tech stories generally start with a virtually stock vehicle, this overview focuses on a more typical 50+year-old muscle car that has seen a host of modifications – just to keep it drivable in many cases. RestoMod cars often feature various driveline swaps, oversize tires and wheels and, of course, suspension alterations. It should be noted that this article is in no way a critique of any of the parts currently installed, just an effort to demonstrate the benefits and versatility of the Aldan American coilover kits.

The Kit

For this Camaro we decided to use Aldan American’s double adjustable coilover system up front and a single adjustable rear “smooth body” rear shock with the factory leaf spring in the rear. The double adjustable coilovers in the front feature 20 levels of rebound adjustment and six compression settings. In the rear the smooth body shock has 11 clicks of adjustment for rebound only (note: a double adjustable rear shock will be soon available according to Aldan American). It should also be noted that the front coilovers allow for two inches of ride height adjustment however there is no adjustment for ride height with the smooth body shock design. To adjust ride height in the rear, differently rated leaf springs can be purchased for this purpose.

The Aldan American kit used here features high quality, 6061- T6 aluminum shock bodies, high tensile coil-springs and nitrogen-charged internals. Warrantied for the life of the shock, these kits include high strength Polyurethane bushings to help deliver long life and overall durability. An optional thrust bushing kit helps when adjusting the shock collar to adjust ride height. We installed on our Camaro.

As mentioned, our test vehicle has a host of aftermarket upgrades, several to the suspension both front and rear. The Aldan American kit fits with these the non-stock A-arm arrangement on this car. As shown here, aftermarket brakes are also not an issue, Aldan American only requiring that these components retain similar-to-stock mounts to accept the coilover shocks we are installing.

Of note with vehicles that have had a number of aftermarket components installed, it is important to first inspect these parts for wear and also “test fit” any new parts before torqueing everything down and heading down the road. For that reason, we checked to ensure that we had proper clearance and shock length within the spring pocket. For that reason, we first tested our Aldan American coilover without the spring and cycled the suspension reaching full compression and rebound. In our case, with the A-arm snubber up against the chassis, the shock still had significant travel length. In addition, with the suspension in full droop, the shock again had additional shock length. Aldan American makes a wide array of shocks that feature longer or shorter travel lengths to fit most applications.

The Luxury of choice

Once again, the beauty of the Aldan American system is that their coilover shocks features a wide array of adjustments for either just rebound (single adjustable) or rebound and compression (double adjustable). When we installed our coilovers, turned the adjustment knobs full counter clockwise until they stopped, which is the softest settings. Next we turned the rebound knob (top of shock) clockwise 10 clicks to set them to the center point. On the lower compression setting knob, we went three clicks firmer (clockwise). These settings are excellent starting points for tuning.

After you drive you vehicle a bit, you can set the shock firmness to fit your personal ride preference. With the rear smooth body shocks, we set our rebound adjustment four clicks firmer than the softest settings since we are using the factory leaf spring rather than an Aldan American coilover shock. These shocks feature 11 points of adjustment so there is plenty latitude to increase firmness when desired.

The ability to change ride height is as much for handling performance, as it is appearance. Most cars benefit can from a lowered ride height as long as the tires and wheels will still retain full clearance from bodywork, most critically the inner fenderwells. In our case, we adjusted the front suspension to avoid a ride angle that is too far down in the front.

In the end, we found the Aldan American coilovers performed exceptionally well and after a few adjustments we found a setting that we liked. For the limited amount of autocrossing we have planned for the car, we can adjust the suspension to firmer settings when needed. Remember the car should be safely supported when doing this so bring your jack and jack stands. Adjustable cornering on demand – amazing!

Step-by-Step Instructions

Our test vehicle for the latest Aldan American coilover upgrade is this 1970 Camaro already equipped with a host of aftermarket parts. RestoMod cars like this can especially benefit from Aldan American coilover upgrades due to their enhanced engine power and performance-oriented owners.

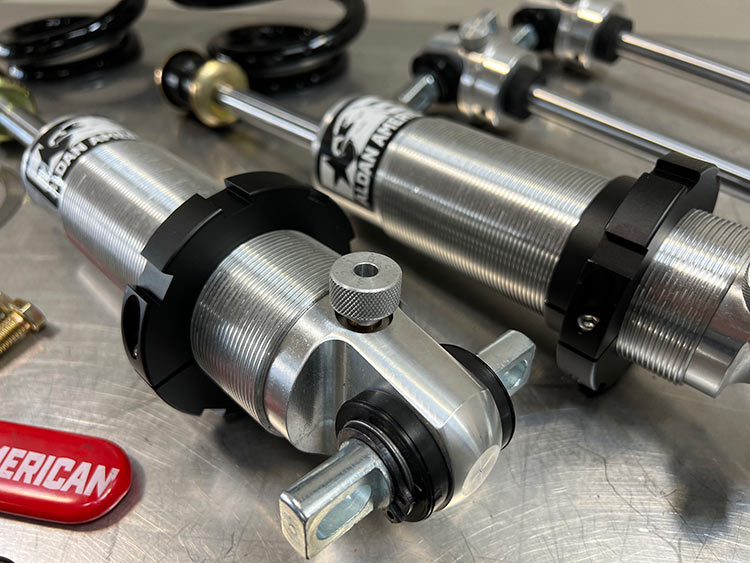

This kit from Aldan American includes a double adjustable coilover shock system for the front and a single adjustable “smooth body” shock for the rear. Both of these shocks are nitrogen filled and place amazing handling versatility in the hands of the driver.

With the Camaro supported safely, we inspected the suspension for any wear or other issues. After getting the green light from our tech department, we set about the installation of the Aldan American kit.

What separates the Aldan American kit from other companies is their attention to detail. Not only do they include an adjustment wrench (arrow) with every kit so you can easily adjust the overall vehicle ride height, but optional (and recommended) parts such as these thrust washers that fit under the coil spring and help make it easier to rotate the bottom spring mount collar can be purchased with the kit.

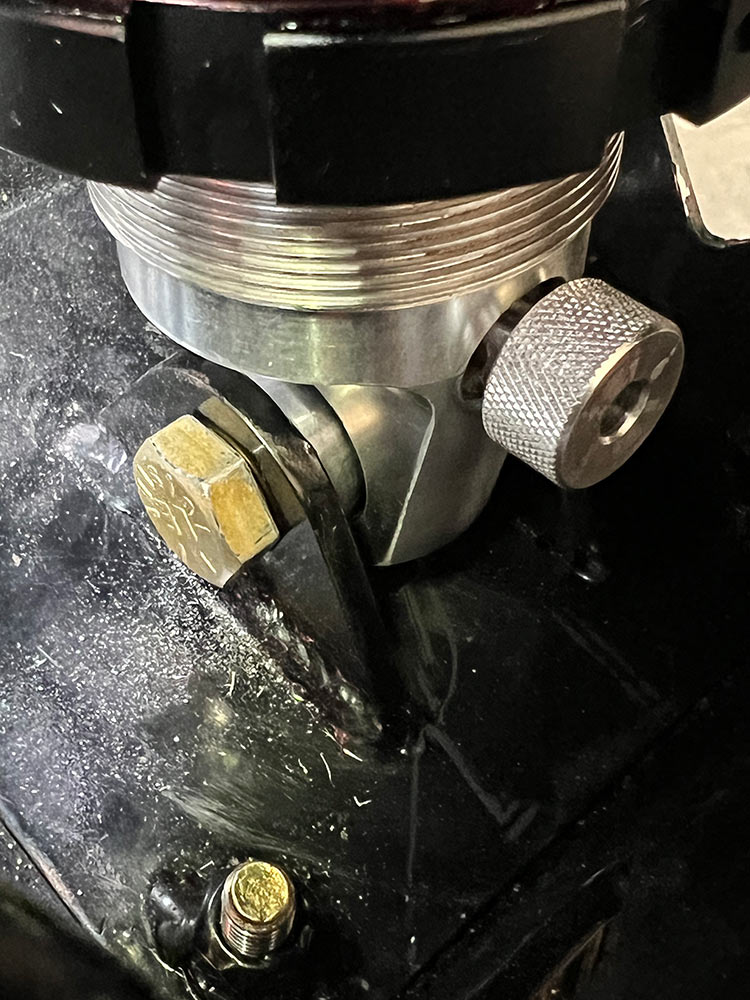

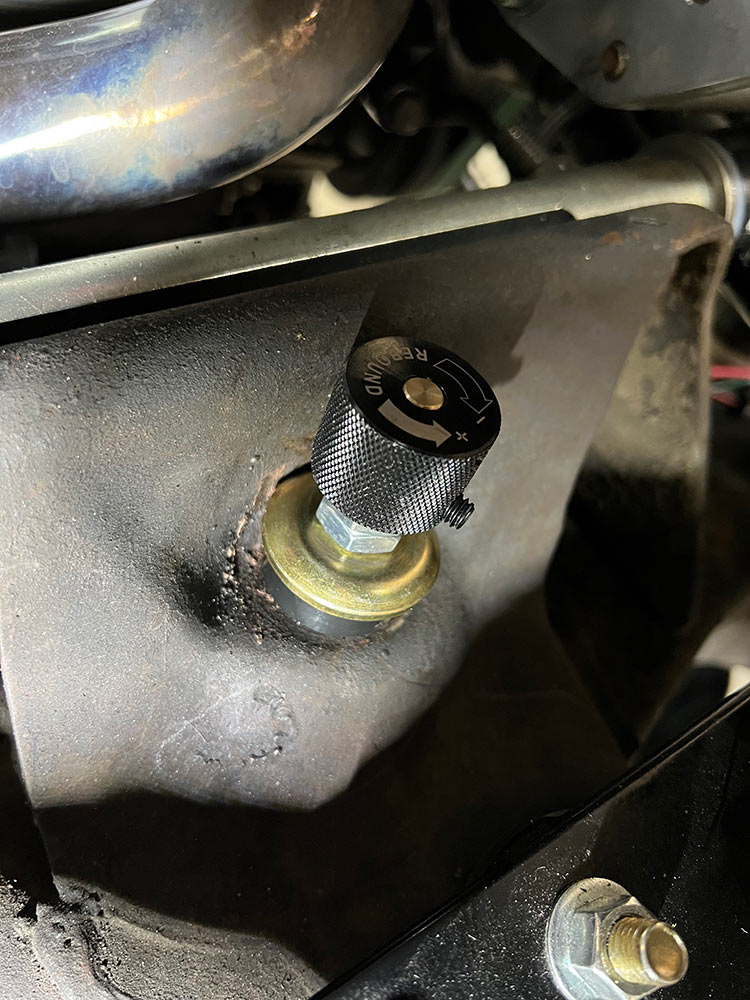

Designed with adjustability in mind, a simple click of this knob alters the firmness settings for this double adjustable shock. Note the clear markings on the knob so you know where you are with your adjustments.

Aldan American also offers a number of different springs rates to fit your vehicle. As our test vehicle was fitted with a small block Chevy engine and a supercharger, they recommended a 550-lb./in. rate, which is generally used on big-block engine vehicles due to the added weight. The usual rate for small block-equipped cars is 450-lb./in. The number “10” in the coding refers to the recommended free length of the spring, uncompressed.

These two front coil over shocks different in one key point: the one on the right is double adjustable with knobs on either end of the shock so you can adjust for both compression and rebound. The other one is single adjustable with one adjustment knob for compression firmness. Also of note the left shock has a T-Bar bottom mount, which can be required in more stock-style applications.

This is a detail photo of the knob at the top of the double adjustable shock. As clearly noted in the writing on the top of the knob, this controls the rebound characteristics – harder or firmer with a twist of the dial.

Our Camaro had undergone a number of changes including aftermarket A-arms, brakes and rotors. Not to worry, the Aldan American kit was compatible with all of these upgrades.

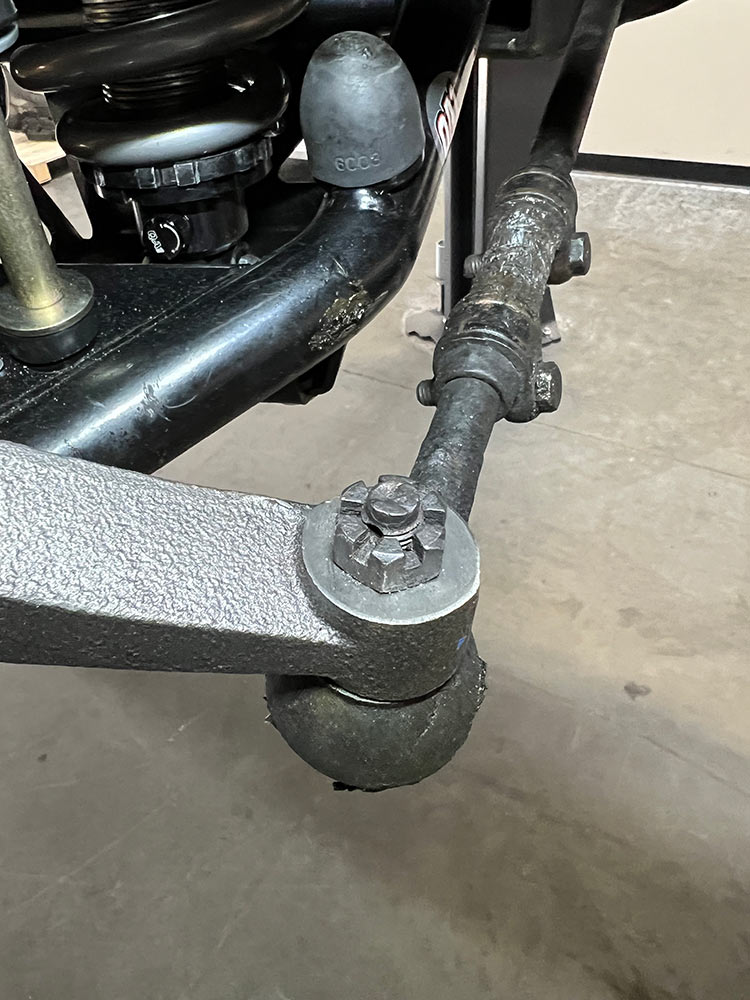

Step one was to remove the tie rod end from the spindle. Make sure not to damage these ends during disassembly or you will have to purchase new ones before you can reassemble the suspension.

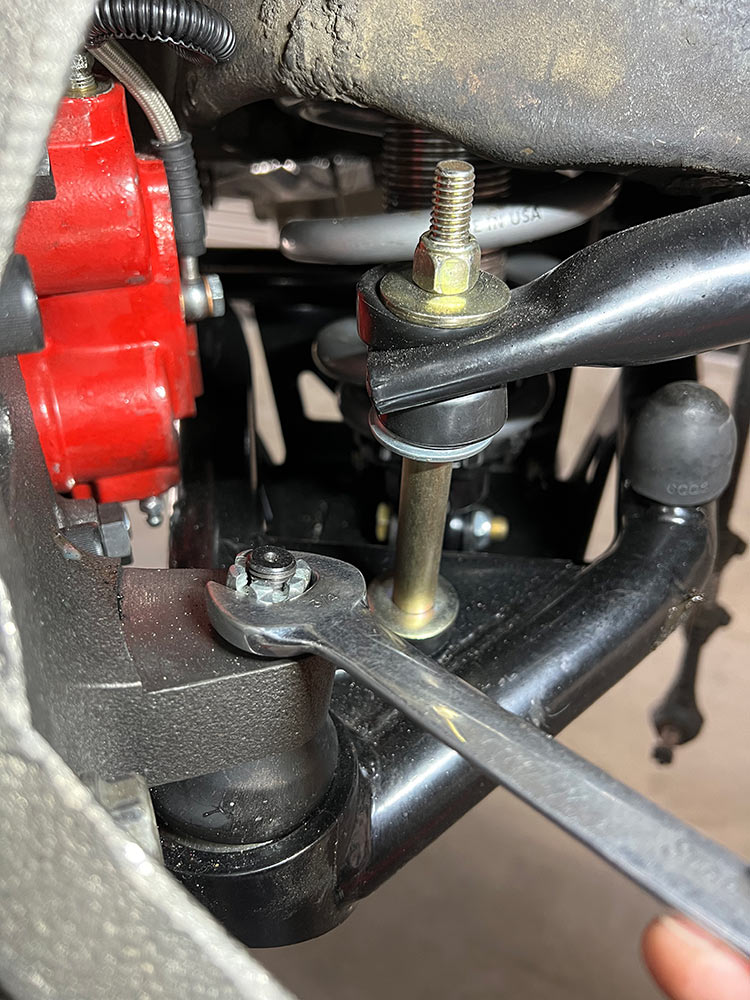

The sway bar links (gold rod with bushings) will have to be completely removed along with releasing of the lower ball joint connection. Make sure you have safely supported the lower A-arm before you dive in as it is under pressure from the currently installed shock and spring.

For ease of photography and general access, we removed the brake caliper and pads and hung the assembly with a wire so as not to over extend the brake line. In reality, you could do the install without completely removing the spindle.

With our spindle out of the way, it is easy to remove of the old shock and install the new Aldan American double coilover system.

With the lower A-arm still supported, we unbolted in the upper shock mount that sits in a pocket on top of the A-arm.

With the upper and lower shock mounting bolts removed, we pulled out the old coil spring carefully making sure to control the power of that spring. These springs can jump out and injure you if not careful. If you are worried use a spring compressor to contain the release.

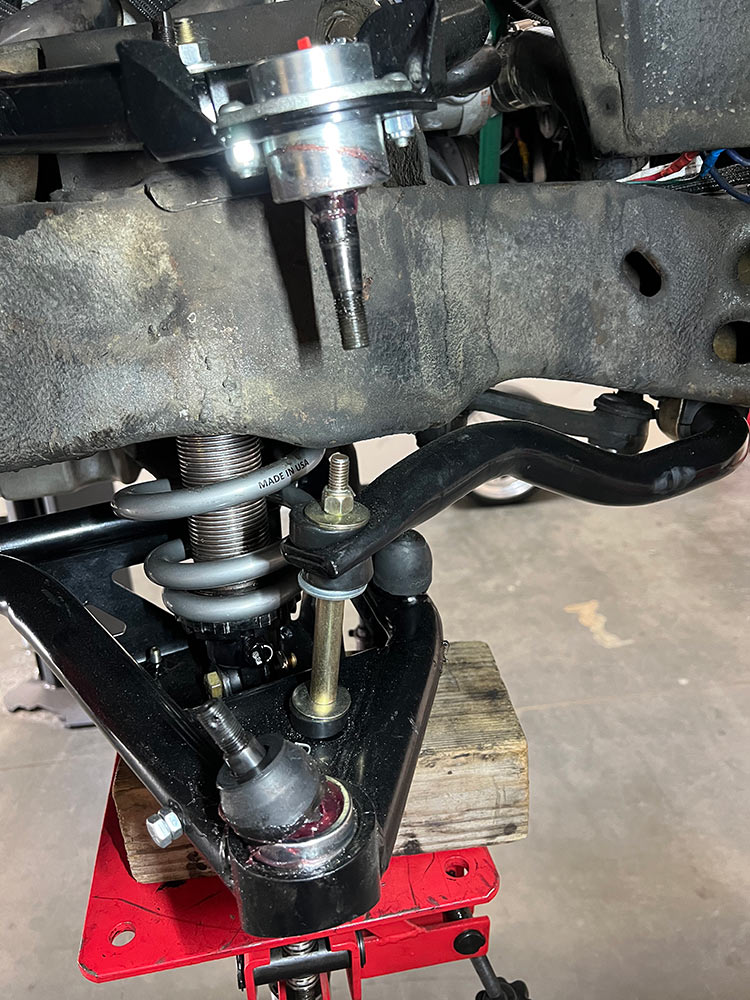

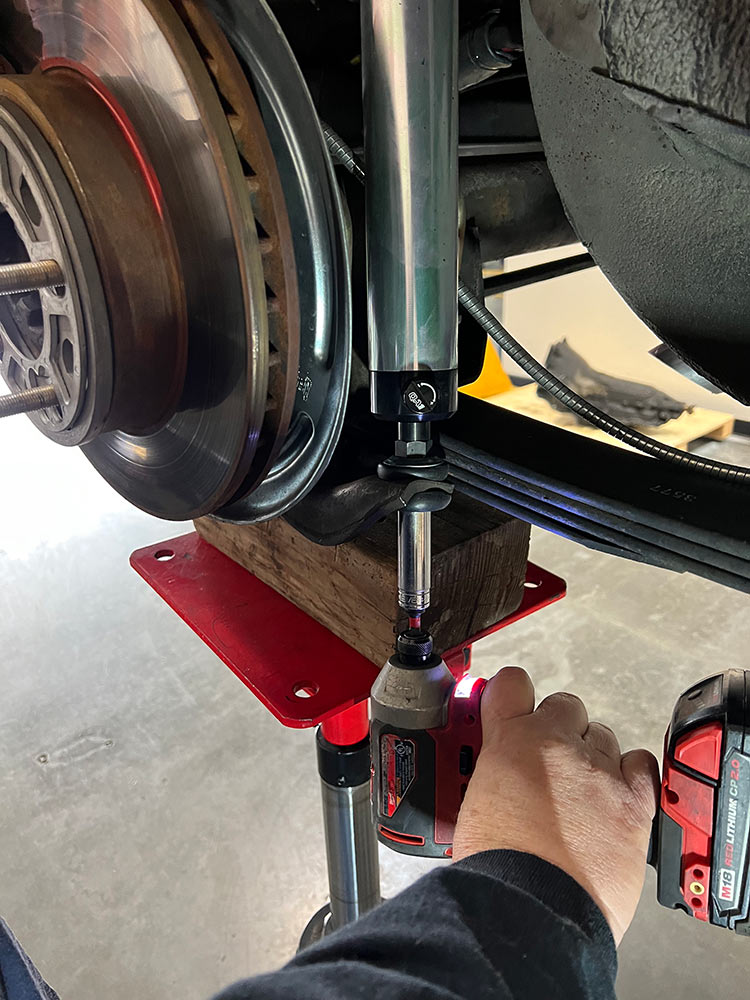

One operation that is required when modifying a vehicle that has aftermarket parts is to test the suspension by “cycling the suspension” to make ensure that the new Aldan American shock does not bottom out or over extend in the chassis. For that reason we started by taking the Aldan American shock, without the spring, and installing it where it will ultimately reside.

With the suspension in full compression and the A-arm against the limiting stop, the shock still clearly has additional travel potential. This reassured us that the shock was the correct length for this installation. Had the shock been a fully compressed (bottomed out), we would have had to select another part with longer “travel” for this application.

As with any Aldan American coilover, we prepared the shock by coating a number of threads of the body with copper anti-seize lubricant. This will allow the collar to be easily turned on the shock to adjust the vehicle ride height.

Next we applied Red All-purpose Grease to the optional thrust bearings and slipped them on the shock body. This bearing kit allows the spring to turn on the shock body when vehicle height adjustments are being made.

The spring slips over the shock body with the smaller end on the bottom. This progressive rate spring is designed to deliver 550-lb./in. compression, perfect for a big block and iron block LS- powered car and small block cars such as our equipped with a supercharger. For small block cars and aluminum LS engine cars without power adders, a 450-lb./in. rated spring is available. Of additional note, the owner of the Camaro noted that the car had issues with bottoming out at times – another reason for the stiffer springs. As an added safeguard, the owner can raise the body if required by turning the collars on the shock bodies.

As a first step, we installed the various cups, washers and bushings used on the end link and poked it through the upper A-arm. We then installed the final parts along with the jamb nuts to loosely hold it in place.

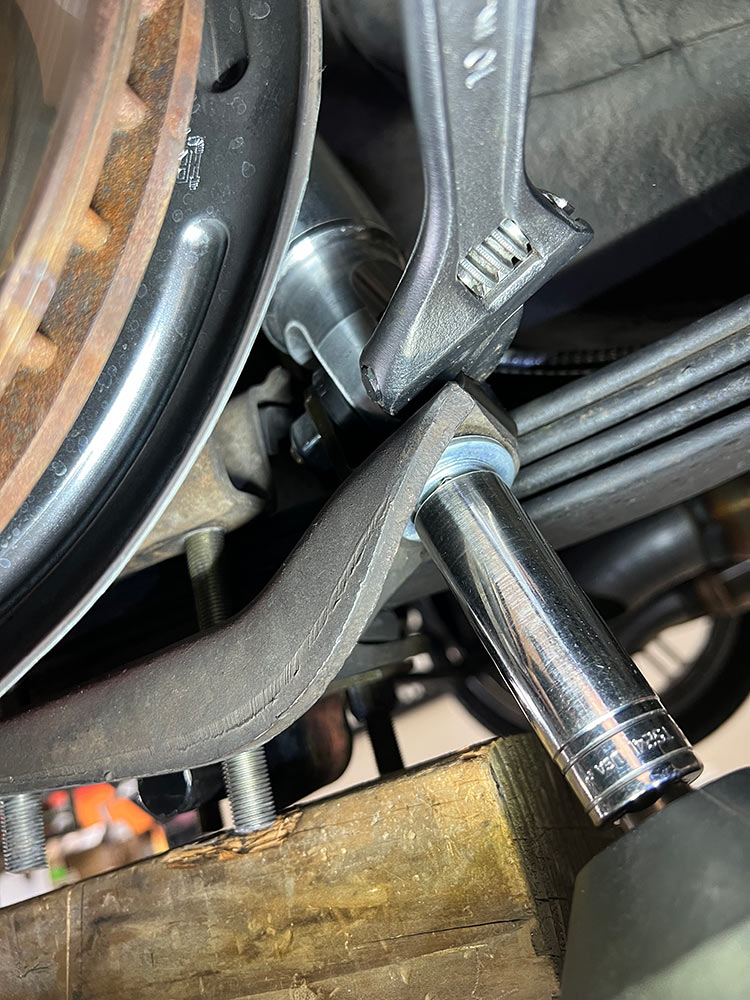

Next we bolted up the lower end of the Aldan American shock into the aftermarket A-arm. It is important to note that the Aldan American lower bushing is 1 3/8-inch wide rather than the 1 1/4-inch mount spacing with this aftermarket A-arm. For that reason we needed to use special offset hardware and bushings from Aldan American to make the connection. Aldan American makes both single bolt and T-Bar ends dependent on the A-arms you are using. For our single bolt system, we torqued the bolt to 55 ft. lbs.

After tightening the top two jamb nuts and installing the adjustment nut, we turned the knob all the way counter clockwise to set the adjustment at full soft rebound. We when turned the knob clockwise four clicks as a starting point. Adjust this setting, after driving, to your liking.

The supplied adjustment wrench allows for easy vehicle height adjustment. This has to be completed with the car safely supported off the ground or it will be impossible to turn the collar.

The rear shock set up is far easier to reach than the front. Remember to support your vehicle safely.

A threaded rod and nut connects the shock to the bottom spring mount like this. We disconnected the shock in this manner.

Two bolts are used to hold the upper shock mount to the chassis. They are easily removed using socket extensions.

These adaptor mounts, designed for this application by Aldan American, allow the smooth body shocks to fit into the factory mounts without modification. Torque these bolts to 55 ft. lbs.

Our Aldan American shock features an adjustment knob for rebound that must be accessible when the shock is installed. This T-bar top mount makes for easy installation.

The lower mount, equipped with the Aldan American adaptor, fits into the chassis in the same way as the original factory shocks were installed. Do not fully tighten this nut yet.

After mounting the top of the shock and torquing the bolts to 35 ft. lbs, the adjustment knob was turned full counter clockwise until it stopped. On this shock, Head Engineer, Gary Nelson, suggested a starting setting of four clicks firm. You can adjust these to your liking after you drive the car for a while. Note that when the car is on the ground, the clearance between the knob and the bodywork will increase.

Be careful not to allow the shock body to turn when tightening the lower bolt or the shock’s upper adjustment knob will not be accessible. For that reason we held the shock body in place with a crescent wrench as we tightened the lower mounting nut. Don’t forget to tighten the top mount bolts, torqueing them to 35 ft. lbs.

Our test case Camaro was initially lowered a full inch over the original height to improve stance and roll center for improved cornering. Should we encounter any fender contact, we can easily raise the body up. Now our Camaro not only looks cool, it has cornering tunability the original factory General Motor’s engineers could never have imagined.