Prowling Around: Make your Prowler corner as well as it looks with coilovers from Aldan American

Photos and story by Cam Benty

If you wandered by your local Plymouth Chrysler dealership between 1997 and 2002, you might have spotted what has now become a highly desirable modern Hot Rod, the legendary Plymouth Prowler.

These concept cars leapt from engineer drafting table to showroom floor with great fanfare about the time the Dot.Com craze was hot. The brainchild of Chrysler Head Engineer, Tom Gale, Prowler utilizes the same coilover suspension design used on Prowler’s faster cousin, the Viper. By the mid-2000’s, most folks had forgotten about these strange beasts. Today they have been rediscovered and for good reason – they are great fun to drive and make a statement even when parked.

Prowler Primer

The Prowler uses a 214 horsepower V6 engine tucked between the aluminum space frame rails of its advanced design chassis. But it’s the cool coilover suspension that intrigued Aldan American’s master of suspension, Gary Nelson, to develop a tunable coilover system that fits neatly into the Prowler chassis without need for cutting or welding. As with most cars of this era, the factory suspension is not adjustable, whatever it was, you had to live with it . . . until now!

One of the key complaints about the Prowler is that due to the fact that it uses run flat tires with hard sidewalls (there is no spare tire), the ride is somewhat harsh especially in highway cruise mode. But now with the Aldan American coilover system, the Prowler suspension can be softened for cruising and stiffened up if performance driving as desired.

Aldan American to the Rescue

The Aldan American kit for 1997-2002 Plymouth Prowlers features front and rear coilover shocks that utilize 450 lb. per inch front and 550 lb./in. rear of compression springs and hydraulic shocks with 11 points of adjustment for rebound. These adjustments are completed by simply turning a knob located on the top of the shock body. That’s a big change from when the car when new and the only way to change ride feel was to bolt in new suspension parts.

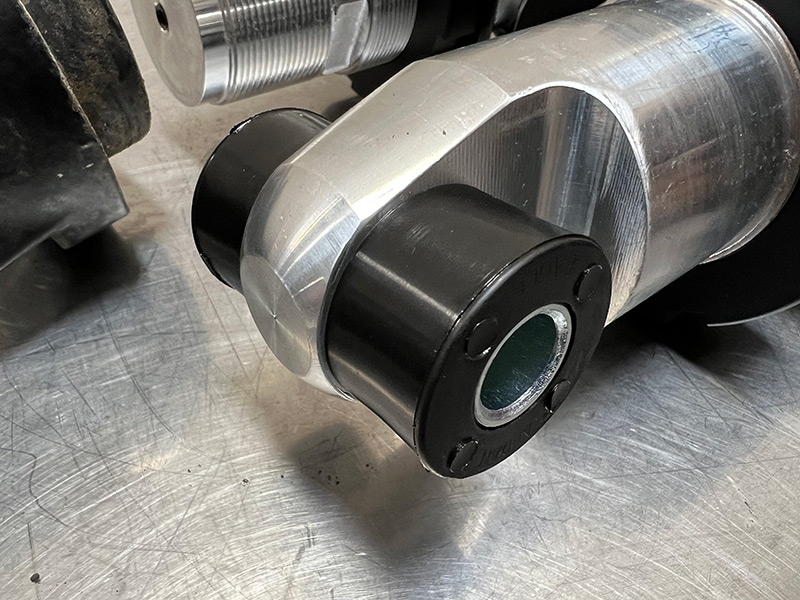

Aldan American coilovers are nitrogen-charged and utilize high strength 6061 billet aluminum shock bodies wrapped with cold-wound, high tensile, chrome silicon steel springs. As with all Aldan American parts, they are 100% American made and fully rebuildable so that after delivering years of on road service they can be refreshed without having to purchase all new parts. Aldan uses polyurethane bushings at the front suspension mounting points to provide some cushioning without compliance.

In addition to rebound adjustment, by using the wrench supplied with all Aldan American kits, the ride height of the coilover can be changed to raise or lower vehicle ride height – and that all important roll center. The wrench fits into the notched collar that serves as the lower mount for the springs on the hydraulic shock body. This adjustment also slightly changes the spring rate of the coilover but only modestly. A shorter overall length coilover that drops the vehicle height is also available (Aldan PN PWLB4).

In the end, Aldan American’s newest coilover package delivers true ride tunability to these very fun-to-drive cars. Remember that the suspension should be realigned on a professional rack to ensure that all of the caster, camber and toe-inch specs are correct. Misalignment can caused excessive part wear and poor steering control. Full ride height adjustment of the front coil requires removal of the coilover and turning the lower spring mount collar.

Prowlers are truly a car that no one ever forgets once they arrive on the scene. Now these modern hot rods can now truly be enjoyed in any setting be it road trip or cruise night. The choice is yours.

PARTS for this Plymouth Prowler Upgrade

- Aldan American full kit (front and rear) – #PWSB4

- AA Kit for front suspension only – #PWSBF2

- AA kit for rear suspension only – #PWSBR2

- AA kit for lowering ride height – #PWLB4

Our Plymouth Prowler was virtually original except for the usual parts replacement through maintenance. It was the perfect showcase for our Aldan American coilover upgrade.

Aldan American offers both front and rear coilovers for any 1997-2002 model year Prowler. The rear suspension coilover (top coilover – the clevis at left is from stock Prowler and is reused) and the front coilover (bottom component) can be ordered in sets of two (front or back) or all four to complete a full car. They also offer a shorter length coilover to lower the overall ride height of the car.

The Prowler is unlike any other production car with huge 295/40R20 rear tires and much smaller 225/45R17 tires up front. These cars originally came with “Run Flat” tires, which maintain their overall shape even when punctured since Prowlers are not equipped with a spare tire.

The Plymouth Prowler was a concept car that came into reality. It is a fun to drive car with a cool shape unlike anything else on the road.

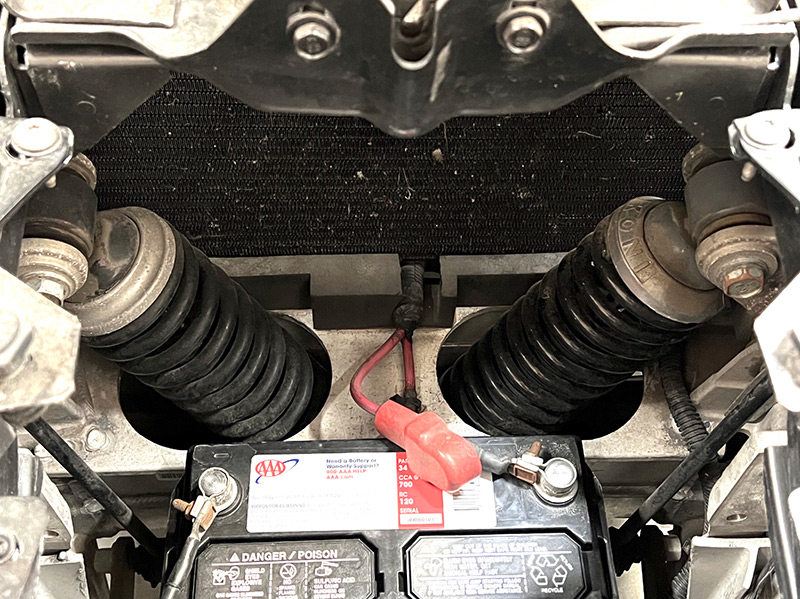

Open the hood of the Prowler and in front of the radiator you’ll spot these twin coilovers. They are easy to remove by removing the two bolts (per coilover) that hold them to the suspension.

The rear suspension is quite different that the front with massive coilovers units on each side. The lower clevis section of the coilover unit will be used again, but the top section is replaced with the new adjustable Aldan American coilover.

Aldan American uses specially formulated urethane bushings for the front mounts. This urethane helps keep the coilover in proper position even when compressed during compression and cornering delivering the optimum in handling efficiency.

This knob is at the heart of Aldan American’s coilover tunability. Positioned at the top of the coilover, it controls the rebound characteristics of the nitrogen-charged shock. Turn it clockwise and the shock is more resistant to rebound (and a harder ride). Turn it the other way and it delivers a softer ride.

An option with most Aldan American coilovers is this series of thrust washers and a single bearing plate (Aldan part # ALD-26). Once in place, this upgrade makes it easier to turn the lower coil spring mount, the adjustment for overall vehicle ride height. We lubricate the thrust washers and bearing plate with Red & Tacky Grease to help them slide easier when in position.

The Aldan American adjustment wrench fits into the lower spring mount. Notches in the mount fit into the teeth in the wrench allowing the mount to be easily turned on the hydraulic shock body.

That same Red & Tacky Grease we used on the thrust washer kit also helps the urethane mount slip more easily into the front suspension mount.

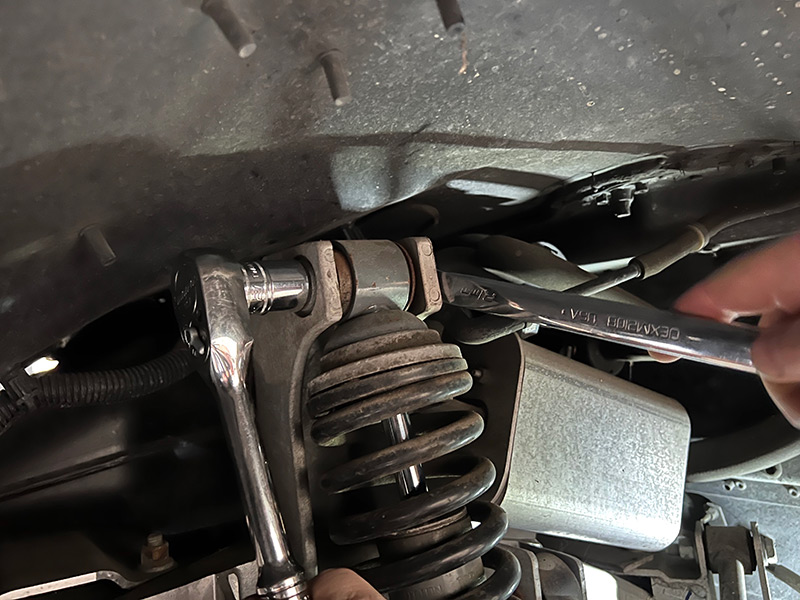

The lower coilover mounts are held in place with bolts located on the underside of the car. The nuts on the other side of the frame section feature tabs that help them stay in place so no wrench on the backside of the bolt is required.

Before removing the upper bolt on the factory coilover, we supported the A-arm with a jack, just to keep some light pressure on the coilover. This makes it easier to remove the attachment bolt.

To release the factory coilover, remove the remaining single bolt that holds it at the top. All of the original coilover bolts will be reused with the Aldan American coilover kit.

Removing the factory coilover is fairly easy and requires only a little bit of wiggling to pull it free.

We dropped in the new Aldan American coilover making sure that the adjustment knob is accessible once in place. Torque the attachment bolt here to 75 lb. ft.

The same holds true for the bottom bolts that also are torqued to 75 lb. ft. The original nut/tab system is also reused and works great.

Moving to the rear, we first safely supported the car and started by removing the lower bolt that holds the saddle to the lower A-arm.

To get the bolt to push through, we tapped on the back of the bolt with a long punch like this. We found the entire coilover removal process much easier with rear tires removed from the car.

Next we removed to the top of the coilover to remove the attachment bolt. Only remove the nut from this bolt/nut system. The bolt is splined so it will not turn.

Here is the splining of the bolt (arrow) that we mentioned. This actually makes it much easier to remove the nut/bolt system as you only need to release the nut and tap out the bolt.

Here you can see how large the rear coilover system is on the Prowler. Remove the entire unit from the car.

Because the front springs are so stiff (450lbs. per inch of compression – 550 lb./in, rear) you may need to take them to a shop that has one of these compressor tools. The coil spring must be safely compressed to help it come apart.

Once compressed, the top cup slides out around the shock shaft and the coil spring is released. We will only be reusing the lower clevis section.

The original factory shock unthreads from the saddle. To grip this notch and turn the shock body requires a special tool to remove. We used a hammer and chisel and the “popped” the shock loose then unscrewed it out by hand in a bench vise. The other method is to use a pipe wrench to loosen the shock from the clevis.

Here you can see the threaded shock body which is almost ready to release from the clevis. You will not be reusing the shock body.

We applied a thin coating of Copper Anti-Seize Lubricant to protect against corrosion.

Once the new Aldan American coilover is threaded into the saddle, it must tightened in place. To facilitate that process, Aldan American created this ingenious wrench/plate (Aldan part # ALD-49) that grips the coilover and threads it into the saddle section. A square hole in the plate allows you to insert a ratchet drive to add leverage for further tightening.

The newly assembled Aldan American coilover and saddle section are now ready to be installed. Note again that the adjustment knob is facing out so it can be reached for further shock tuning after installation. Torque both the top and bottom attachment bolts to 70 lb. ft.

This is another view of the rear suspension after installation. We can also adjust the ride height of the Prowler up about an inch by using the Aldan American wrench.

The adjustment knob on both the front and rear coilovers has this knob that controls rebound valving. Aldan American recommends turning the knob fully counter clockwise until it stops then six clicks in the clockwise direction to set it in the middle of the range. There are 11 points of adjustment for rebound valving on both the front and rear coilover units from Aldan American.

Our Plymouth Prowler now has adjustability way beyond what the factory offered some two decades ago. The ability to adjust the rebound valving of the suspension is a game changer for these very cool and fun to drive vehicles.

-

Coilover Kit – Plymouth Prowler 1997-2002 Front and Rear

Price range: $1,665.99 through $1,697.99 This product has multiple variants. The options may be chosen on the product page