Chevy II Cornering Cure

Making your classic 1962-67 Chevy II achieve handling perfection with an Aldan American Coilover upgrade

By Cam Benty

Photos by Cam Benty and Gary Nelson

The 1962 Chevy II was a car ahead of its time. A small but efficient package with plenty of interior room for the family, the 1962-67 Chevy II was a great choice for buyers on a budget and sold extremely well. In just six model years of production, Chevy sold almost 1.2 million Chevy II’s.

But performance car enthusiasts were drawn to these cars for another reason – power to weight ratio. While many Chevy II’s were powered with a straight 230cid, six-cylinder engines, a 283cid V8 engine backed with a 4-speed manual transmission could be had right from the dealership. With a total curb weight for a small-block powered 1962-5 Chevy of well under 3000 lbs, owners found delight in tearing up the drag strips across America with these quick little machines. Best of all, if a 283cid engine could fit under the hood, so could a 400+ horsepower small block. Now we’re talking performance!

But while the underhood performance of the Chevy II was an easy upgrade, the handling side maladies took a lot more effort. For the first Generation X-body Chevy II’s, General Motors used basically 1950’s suspension technology. The Chevy II’s front suspension featured a basic coil spring and shock arrangement above the A-arms and a completely inadequate single leaf rear spring and shock to control the rearend. As any performance fan will tell you, these parts were “bargain basement” underpinnings meant to keep the factory build costs down.

Aldan American 1962 – 67 Chevy II Coilovers

The engineers at Aldan American have applied their advanced design coilover system to the 1962-67 Chevy II platform. Their newest kit includes all of the pieces needed to install a single or double adjustable coilover/shock system into the factory suspension. At the heart of this system is the use of high-grade components like cold-wound, high tensile Chrome Silicon steel coil springs, nitrogen-charged shocks, heavy-duty hardware and ride height adjustment wrench.

The beauty of the Aldan American system is the ability to not only adjust the shock absorbers for compression and/or rebound but the spring rate of the coil (usually dependent on the weight of the engine) and the ride height of the car to lower the roll center for better cornering. Single adjustable shock valving refers to a shock that can be adjusted for compression only. Double adjustable refers to adjustability for both compression and rebound. Turning knobs located at the top and/or bottom of the shock allows the owner to complete these adjustments in seconds.

A billet collar (that rides on the shock body) serves as the bottom mount for the coil spring. By rotating the collar up or down on the shock body with the Aldan American-supplied wrench, the ride height of the vehicle can be altered. Aldan American pre-selects the choice of coil spring rate to the details you provide when ordering. If there is an engine change or you want stiffer springs for competition driving, you should mention that at the time of purchase. Aldan American has a number of differently rates coil spring available.

The Build: 1962 – 67 Chevy II Coilovers

The Aldan American Coilover kit we installed featured double adjustable shock valving – adjustments to compression and rebound firmness. In our case the Chevy II now has six setting for compression firmness and 11 settings for rebound. A single adjustable coilover is also available this application but only with compression firmness adjustability. For many owners, the single adjustable system is more than enough. As an added benefit, the single adjustable coilover kit comes with an even more affordable price tag.

Our total installation time for the Aldan American Coilover kit took an afternoon – most of our time spent positioning the upper shock mounting brackets. In the rear, we only made a shock change and left the rear leaf spring in place. For street driving, we found retaining the rear leaf and installing a double adjustable Aldan American smooth body shock gave us a great ride and the latitude to tune for performance driving when required.

In the end, our Aldan American-tuned coilover system provided a major improvement in the ride quality of our 1963 Chevy II. The techniques shown here will apply to not only the first X-Body Chevy II’s (1962-5) but also the 1966-67 models.

1963 – 67 Chevy II Coilover Install Walkthrough Steps:

Our classic 1963 Chevy II looks none the worse for nearly sixty years of road wear. This specimen features a 350cid engine and some light modifications, perfect for our Aldan American Coilover upgrade.

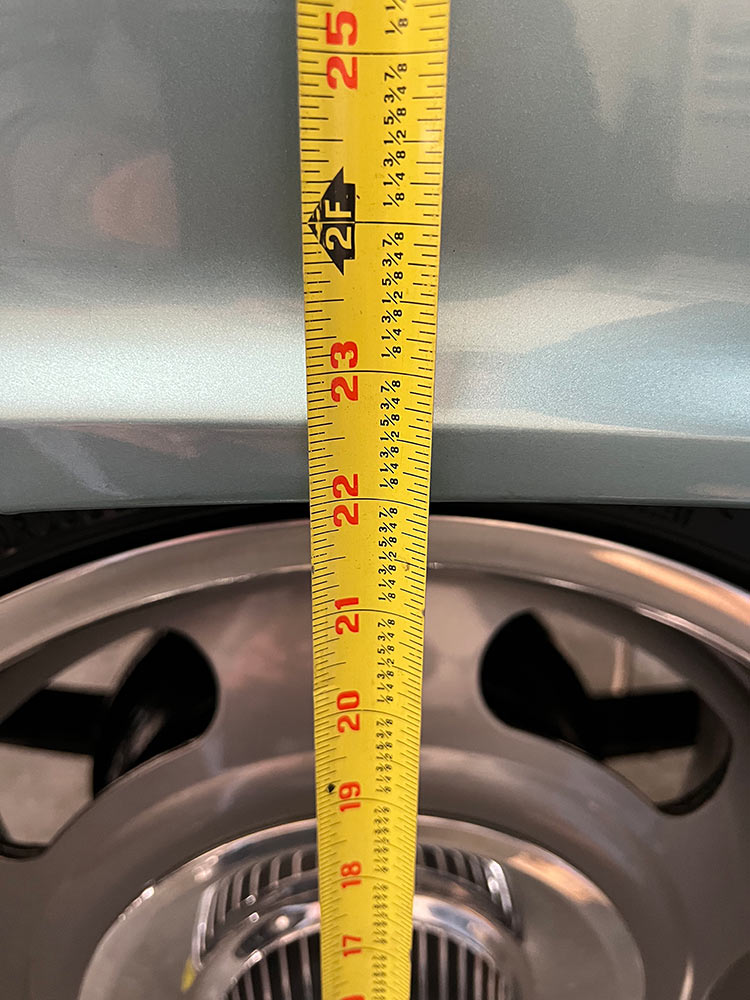

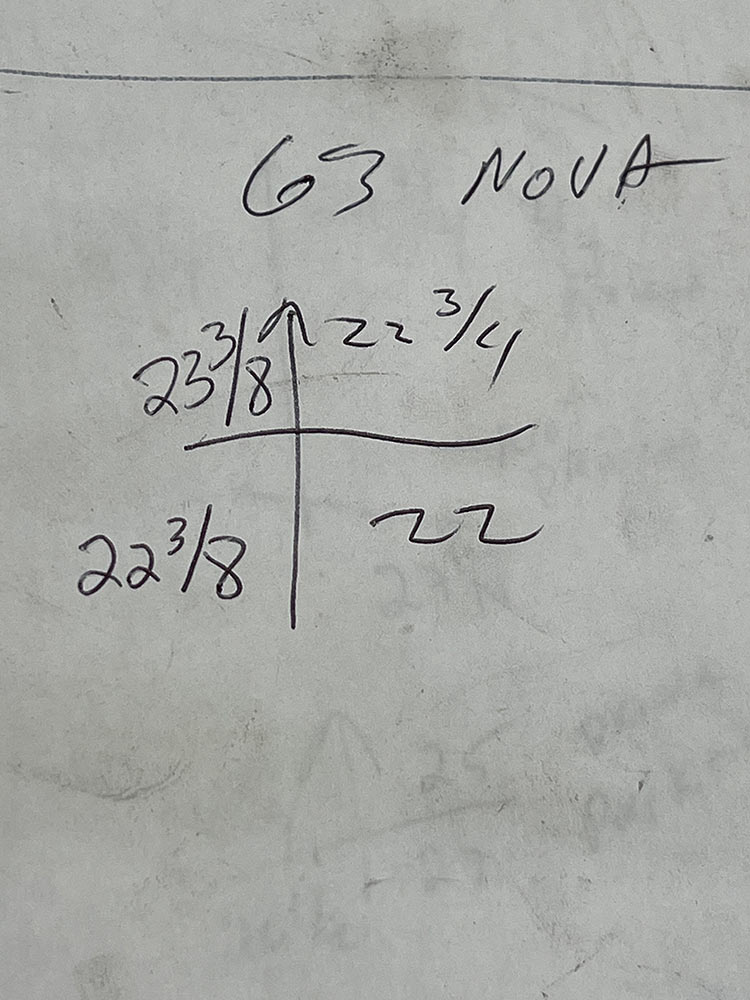

Step one with any upgrade of this type is to check the height of the body front to rear and left to right. We do this by placing the car on a flat surface and measuring from the edge of the fender lip to the ground. Note that the rear fender lips are lower to the ground than the front simply due to the design of the body so you cannot compare the front to back figures when setting ride height.

These measurements denote the height of the fender lips – left to right and front to back. Our Chevy II was not bad with a slightly higher driver’s side than passenger side – but very consistent – front to rear. We will have the ability to correct this issue with the Aldan American height adjustment wrench.

Aldan American has simplified the science to upgrading older vehicles to present day suspension technology. This kit not only improves the ride and handling of your vehicle but also provides complete adjustability for compression and/or rebound – for a very reasonable price. This kit features double adjustable shocks and coilovers front and rear.

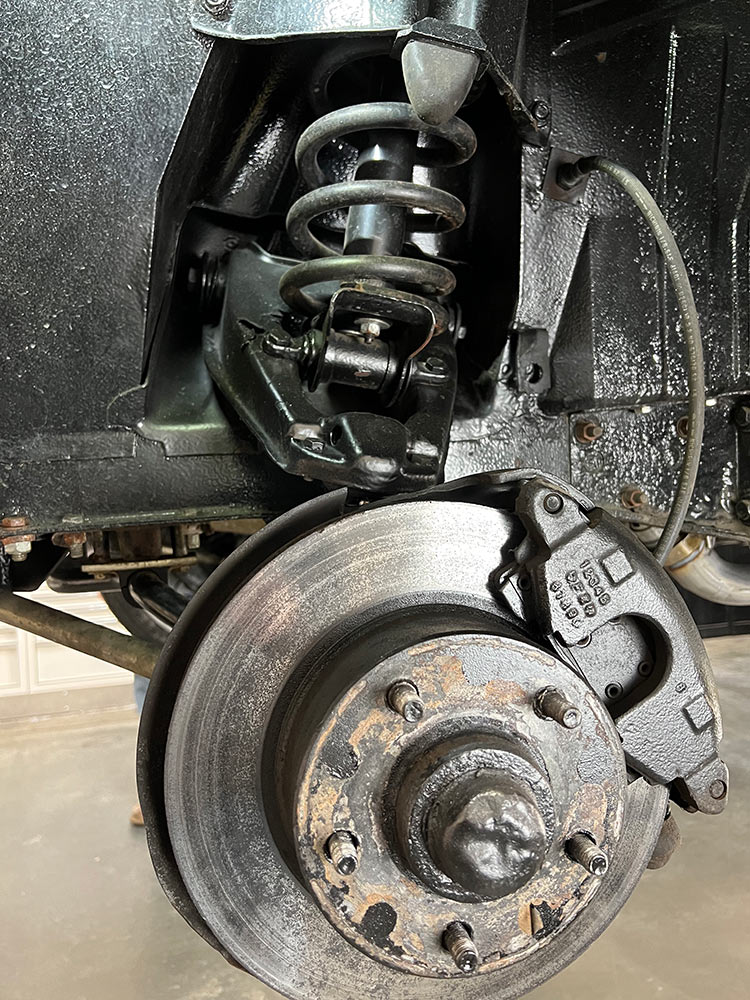

Our Chevy II had already been “up fit” with 17-inch American wheels and high performance tires. With Aldan American suspension kit in place we will be able to maximize tire fitment within the Chevy II’s original wheelwells.

Aside from the front disc brake upgrade, this suspension sports all of the original parts as delivered from General Motors. The Aldan American Coilover upgrade is compatible with either front disc or drum brakes.

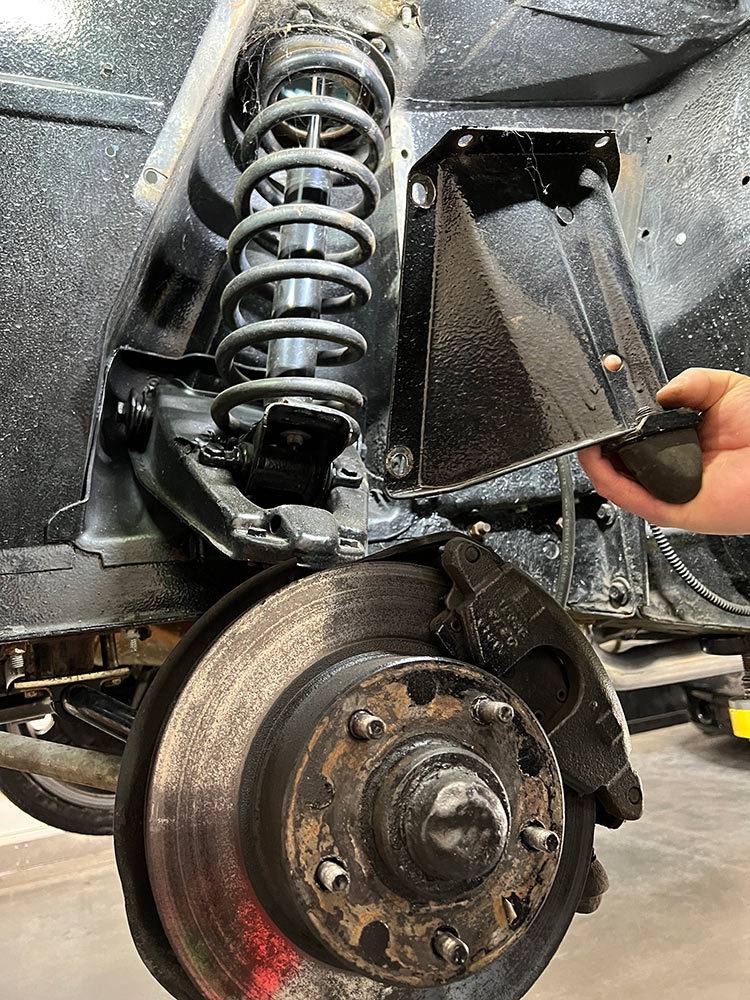

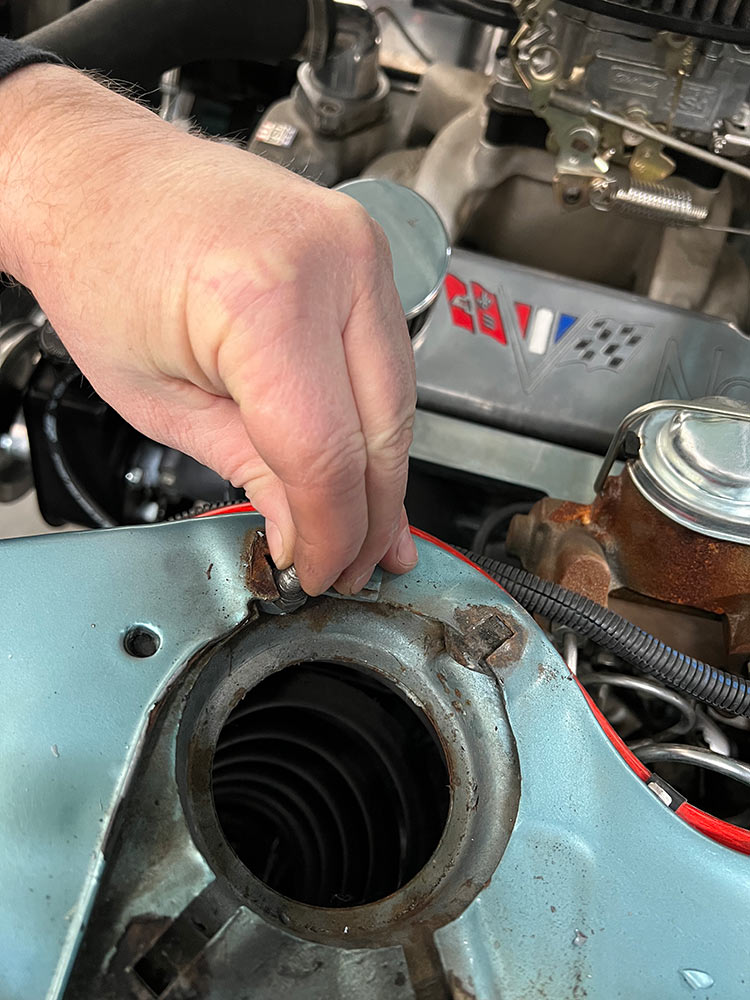

Step one is to remove the protective shock/spring cover that sits above the upper A-arm. With these cars, the factory A-arm and spindle will not have to be touched to install the Aldan American Coilover kit.

These shock and coil covers require the removal of the four bolts and nuts that hold it in place along the sides. Do not forget these two bolts that must be removed from the top of the fender under the hood.

As noted, there are six bolts holding the cover in place. This photo shows the position of those bolts – four on the side and two on the top. With the cover removed the coil spring and shock are now accessible.

Next we disconnected the nuts, retainer and rubber cushion from the top of the old shock.

The shock tower bracket is held on with four nuts – the bolt heads captured in the fenderwell as shown here.

Back under the hood, we needed to remove the nuts that hold the old shock to the lower mount. Two nuts hold the old shock to the bracket, the outer of the two visible here. The other is on the other side of the bracket. The old shock is then slid upward and out of the chassis through the fenderwell opening under hood.

We removed all but one of the remaining bolts that retained the upper shock bracket. This bolt will help us when aligning the new top Aldan American bracket.

To remove the original coil spring, it must be compressed with a spring compressor. We dropped the spring compressor down inside the spring through the opening the fender in the engine compartment. We aligned the brackets within the spring coils (arrows) and then compressed the spring by turning the internal threaded rod. By turning the rod, the brackets are drawn together and the spring is compressed for easy removal.

Finally, remove the lower shock mount by removing the bolts that attach it to the upper A-arm.

We next installed this Aldan American lower shock mount bracket using the same holes that served as the mount for the original shock mount. This bracket is much stronger than the factory unit by design. The Aldan American coilover will support the entire suspension rather than the separate coil and shock used in the factory suspension system and thus requires thicker, stronger Aldan American bracketing.

As with all hardware used in in the Aldan American kit, we are careful to torque the fasteners to spec. In the case of the 3/8-inch Aldan American bolts shown here, we torqued them to 35 ft. lbs.

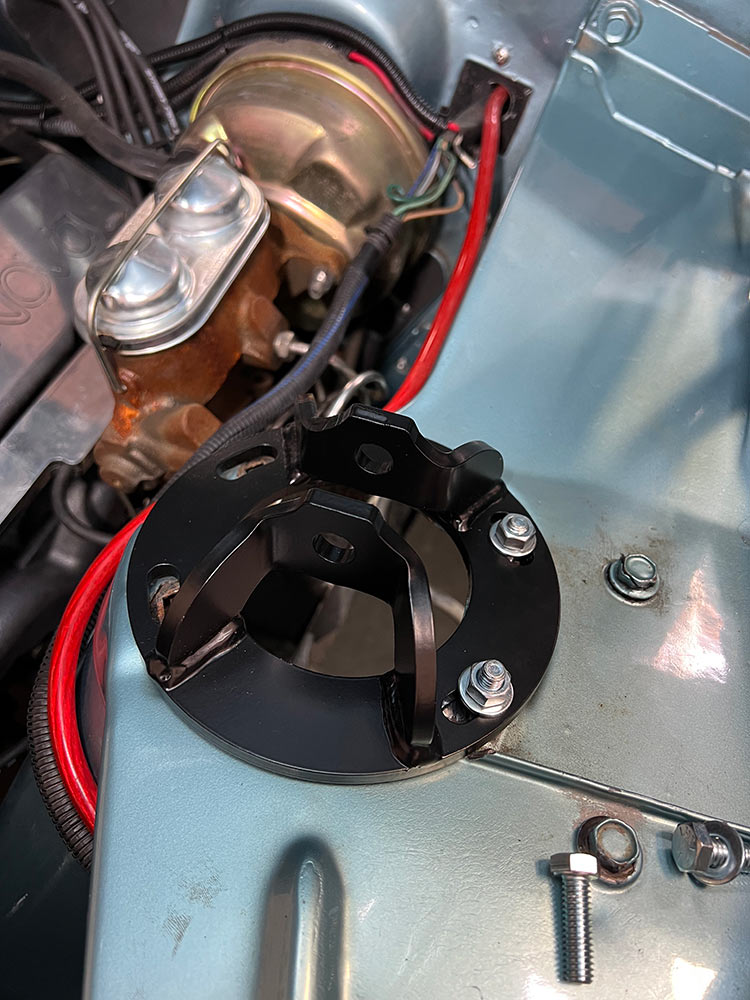

An exclusive Aldan American design support system, this circular mount and the crescent brackets help to “flatten” the point where the coilover connects to the underside of the fender within the coil spring tower. In our case, we used one crescent-shaped bracket on the inside of the spring tower and two on the outside. Our logic behind this arrangement will become clear in the next few steps.

The top of the fenderwell, under the hood, may have this factory-welded seam that will keep the new upper shock bracket from laying flat on the fender. If this is the case, mark where the rib needs to be cut out with a grinder and remove it.

After grinding out this rib, we positioned the upper shock bracket to make sure we had enough clearance. The bracket should lay completely flat on the fender.

As noted, the shock tower bracket and other fender components within the Aldan American kit are called to do more than the original parts. For that reason, the holes that hold the upper shock bracket in place will need to be drilled out for the larger hardware – Aldan American-supplied hardware of course.

These washers (supplied in kit) are used to fill the gap between the upper and lower sections shown here. Filling this small gap helps make for a much more solid mount when everything is torqued in place.

This close up shows the loose set up of the crescent bracket and circular mount in position. Also of note are the washers (arrow) that were installed in the previous step.

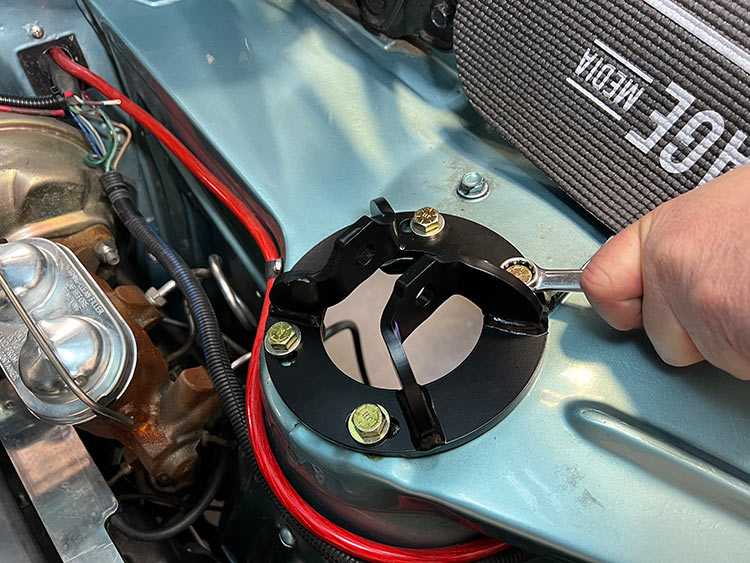

The upper shock mount bracket uses four bolts to hold it in place. These bolts should be torqued to 35 ft. lbs.

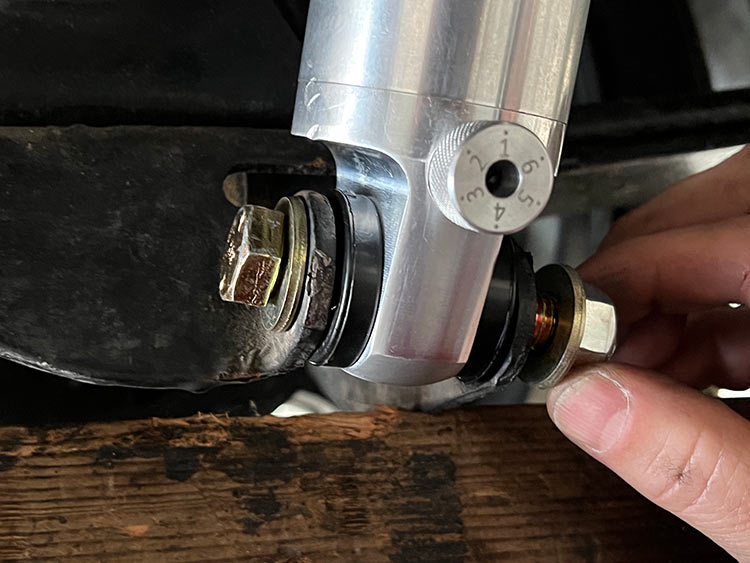

With the double adjustable coilover kit, you can adjust for both compression and rebound. This knob (not present on single adjustable coilover) gives you six points of compression so you can dial in the firmness of the shock. It is recommended to start with the #1 setting, which gives the softest ride.

The top of the coilover assembly attaches to the upper shock mount bracket like this. The hardware is supplied with the kit and will ultimately be torqued to 60 ft. lbs.

To finish off the Aldan American coilover install up front, the bottom end of the coil over is slipped into our new bracket and locked in with this heavy-duty hardware. We torqued the lower bolt to 60 ft. lbs per the specs supplied with the instructions.

Turning this knob at the top of the coilover sets the rebound adjustment of the Aldan American double adjustable coilover. We started by turning the knob counter clockwise until it stopped and then back three clicks clockwise as a starting position. Once we have some experience driving the car we can tune it to our requirements.

This specially designed wrench from Aldan American comes with every kit. By turning the coilover spring collar mounted on the shock body up or down, you can raise or lower the vehicle. Aldan American recommends never lowering your car more than two inches and always checking to make sure the tires do not come in contact with the fenders at any point of their travel.

Moving to the rear of the Chevy II, we started by supporting the bottom of the axle and then removing the factory upper shock mounts. They are held in with two bolts. Luckily, the nuts are retained within the body.

With the top of the old shock disconnected from the chassis, we removed the bolt and nut arrangement that holds it in place on the bottom.

We removed the upper shock mount from the old shock and set about installing our new Aldan American bracketing. Aldan American’s lower mount (black bracket) fits into the stock shock mount in this manner.

Because the threaded bolt that connects to the factory mount will not be accessible once the mount is back in the chassis, it is critical to torque the nuts that hold it in place in a vise off the car. Torque these nuts to 50 ft. lbs.

We loosely installed the new hardware through the upper shock mount bracket making sure that the adjustment knob is facing toward the center of the vehicle for easy access (again, this only applies to double adjustable system). The attachment bolt/nut should run from the back of the car to the front – the side with the nut toward the front of the car. Torque this bolt to 60 ft. lbs.

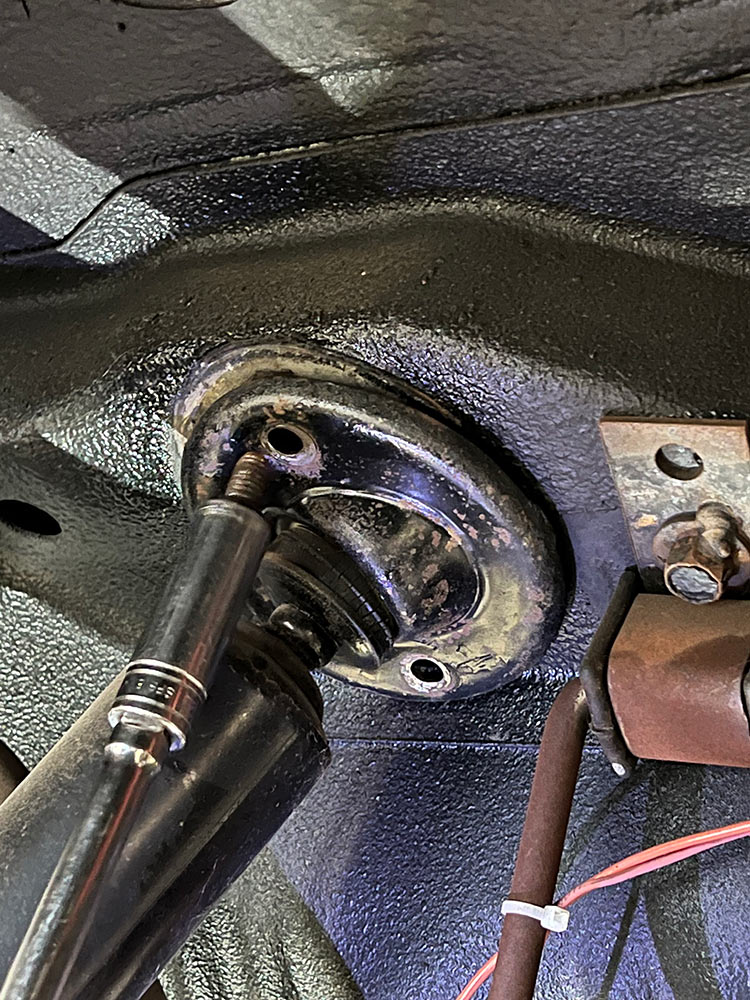

The factory lower shock mount saddle had been squeezed down over time through the use of less performance-oriented shocks so it was too narrow for the new Aldan American shock end. To open up this saddle, we used a series of nuts and washers on a threaded rod. The washers are positioned against the nuts on either side of the saddle. By turning the nut on the right so that it presses on the right side washer, it widens both sides of the saddle. You may or may not have to perform this operation but its good to know how to remedy the issue.

The Aldan American hardware slips into the lower mount in this manner. Once again, the bolt slips in from the back of the car and the nut is on the front side. The adjustment knob for compression is set for #1, the softest setting, as a starting point. With the top knob (double adjustable system only), there are 11 settings for rebound firmness. Turn the knob fully counter clockwise until it stops then back three clicks as a starting point.

Torque the lower shock mount bolt to 60 ft. lbs. Note that we retained the original single leaf spring. The Aldan American smooth body shock is designed to work with the leaf spring suspension design.

Our Chevy II experienced a dramatic makeover through the installation of the Aldan American Coilover kit. Now not only can we adjust for frontend ride height, but for compression and rebound firmness at all four corners. For the autocross enthusiast, this is a huge bonus. For the street machine enthusiast, it brings the Chevy II ‘s ride quality up to current technology. And that’s a great thing!