Made In the U.S.A – The Aldan Advantage

Aldan American suspension products are made here in the U.S.A. So what does this mean for quality and performance when comparing to other products in the market?

There are a lot of great suspension products in the market today to help your vehicle perform better on the road, at the track, lowering, eliminating diving or putting power to the ground for improved traction.

At Aldan we’ve been setting up vehicles with our products and other manufacturers suspension components for over three decades. We’ve seen a lot over this time and the Aldan products you see today are a testament of what we’ve found works best for our customers for their specific applications.

Having our sub-components made here in the U.S.A, in house and locally whenever possible helps us maintain quality. Quality sub-parts allows our products to withstand high horsepower applications and non-traditional vehicles (Lowered Corvette’s, drag cars, classic trucks, etc.) over longer periods of time when comparing to lesser grade products and materials.

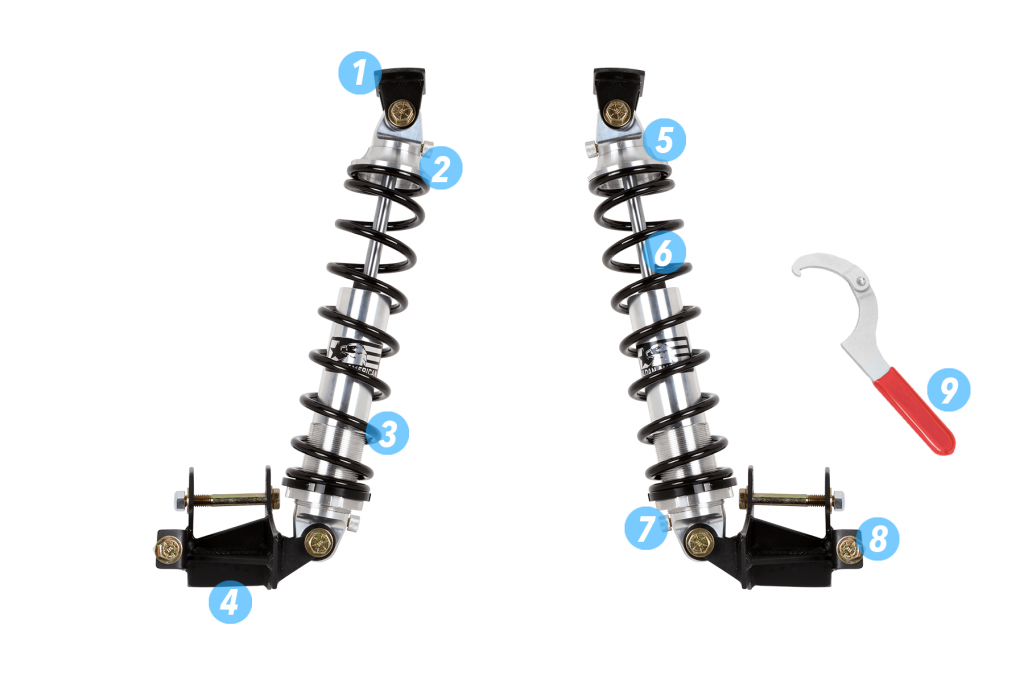

Here’s some of the elements that go into an American made coilover and suspension line:

Coilover Shocks

CNC machined shock mounts from 2.0” solid bars of aircraft grade, 6061-T6 billet aluminum. This design and material is incredibly strong and ultra-light weight when comparing to forged aluminum and steel-welded, loop style mounts.

One-piece seal design built to handle whatever road you’re looking to take. Low friction, Viton seals & o-rings allow our seals to handle extreme heat and abuse. Black anodize finish allows removal so these shocks can be rebuilt, revalved or serviced when desired.

Heat-treated, high strength shock shafts that are chromed and finish ground before final assembly drastically reduces seal friction, providing a longer shock life.

Coilover Springs

Coil springs are made all over the world. We prefer coilsprings made here in the USA for several reasons. Many US spring manufacturers have been developing and perfecting their spring technologies for over a century. Through racing, testing and developments in higher strength, lighter weight spring materials – American coilsprings are of some of the highest quality available on the market today.

What is the best material used in coilover springs? Chrome Silicon Steel. Chrome Silicon steel is the latest in spring technology. This steel material holds it’s consistency longer over time and is less prone to bending or twisting under hard cornering and acceleration. Chrome Silicon Steel is lightweight and higher strength than basic types of spring material.

Adjustable Shocks

The benefit of adjustable shocks and coilovers is that you can control the speed of the shock. Springs hold up your vehicle and shocks and shock damping are what control the spring. Adjustable shocks allow the ability to fine tune your suspension performance. Rebound adjustable, double adjustable, triple adjustable are the most common types of shock adjustment.

The components that go into making a shock adjustable are key. High quality sub-components and low friction materials in the adjustment design will provide greater accuracy and consistency even under the most extreme uses.

Suspension Kits

Converting a vehicle to coilovers or adjustable shocks may require chassis components, brackets or suspension kits of some kind.

When you’re shopping for a all in one solution, buying high quality parts from a company that has done their homework and research to make everything work together is key. Laser cutting makes for precise bores and lines on steel parts. This makes for high quality welds and bolt fitments under final assembly.

Look for CNC laser cut brackets and suspension parts when updating your suspension. Aldan brackets are TIG welded for greater strength over other styles of welding.

Bracket finishes. In the U.S.A. we have requirements in place for coating and plating companies to use non-toxic paints and powders. In regards to powdercoating, we have some of the best here in the states. Our coaters and platers use the same processes and quality checks that they use with their military and aerospace clients.

Having the shocks, brackets, hardware and springs all fit together and work properly is a great feeling. This is something we take pride in here at Aldan to offer products that do the job, last and are made here in the U.S.A.

Shock Accessories

Bushings, tools, bearings, adjustment wrenches – The tighter the tolerances and the more care and precision that go into these parts help round out the entire experience of making a successful suspension upgrade. The little things always matter.

High-end polyurethane for bushings, American made rod ends and spherical bearings all make the difference in fitment and products designed and built to last.

Buying products made in the U.S.A. is investing in something that is going to last.