Maximum G-Force Mustang

Upgrade your 1964-73 Mustang’s handling with high-tech parts from Aldan American

By Cam Benty

Photos by Cam Benty and Gary Nelson

When the Mustang arrived on the American landscape in March of 1964, it cast the die for all the fun to drive, compact, “Pony cars” to follow. With crisp steering, solid performance, and good – for the era – handling, it was a big hit right from the start. However, over the last five decades, the goalposts have moved dramatically as we redefine what we perceive to be a “great handling car.” Today these classic Mustangs can benefit from the application of modern-day, high-tech handling component enhancement.

Aldan American has created a kit that allows classic Mustang owners to apply an advanced design, adjustable coilover shock system to any 1964-73 Mustangs. Our 1966 Mustang coupe proved to be the perfect model to demonstrate this transformation. The entire Aldan American coilover upgrade takes no more than an afternoon to install and requires only a few simple hand tools, a jack and some sturdy jack stands.

The overall handling improvement is instantly recognized with the Aldan American kit. Not only is the handling much crisper, but Mustang owners now have a tunable system allowing them to affect ride quality with the turn of a knob located on the coilover body. One additional benefit, a signature Aldan American advantage, is the ability to adjust not only ride firmness but also vehicle height. The easy-to-change vehicle height adjustment benefits both the aesthetics of the Mustang and the car’s cornering ability, something the Ford engineers back in 1964 could never have envisioned.

About the Aldan American Coilover Kit

The Aldan American coilover kit features a pair of front coilover shocks that can be purchased as either single adjustable (eleven settings of rebound control) or double adjustable (both rebound and compression adjustment). The front shock system also includes shock tower reinforcement bracketing, hardware and easy-to-follow instructions. In the rear, Aldan American supplies a set of very cool “smooth body” shocks that fit into the factory mounts without modification. The upgraded Aldan American hardware is also included with these shocks.

As noted, key to the Aldan American system is the ability to adjust the suspension for rebound (single adjustable coilover kit) or both rebound and compression (double adjustable kit) when desired. These adjustments can be made by turning the appropriate knob located on the exterior of the shock housing. With 11 points of adjustment for rebound and 6 compression-setting adjustments (double adjustable shock only), the driver can stiffen or soften the vehicle ride instantly without having to dismantle the suspension. These kinds of adjustment are particularly helpful if you plan to drive your Mustang in an autocross or slalom competition where stiffer suspension settings can help keep the tire in contact with the road surface for better traction, either a straight line or during cornering.

In addition to the shock adjustments, the ride height of the vehicle can be lowered as much as two inches from stock height by turning a collar located on the shock body. A wrench, supplied in the Aldan American kit, makes it easy to turn this collar (with the vehicle safely elevated on jack stands or a lift) and change overall ride height. By reducing the vehicle ride height you drop the roll center, the theoretical center axis of the car on which it rotates when cornering. If all else is equal, a car with a lower roll center will slip around a corner faster than a vehicle with a higher roll center. The only limit with regards to lowering the ride height of the car is the tire/wheel clearance within the fender openings. It is important that the tires never come in contact with the fenders or the tires can be damaged or, worse yet, the tire can be misdirected during cornering, negatively impacting steering control.

Suspension Makeover for our 1966 Mustang Coupe

Follow along as we overview the suspension makeover of our 1966 Mustang coupe from stock to the hot handling ponycar with the Aldan American coilover suspension system. The handling improvement and incredible tunability delivered by this kit are truly shocking!

Pun intended.

Source: Aldan American | aldanamerican.com | 310.834.7478

1966 Mustang coupe

Our 1966 Mustang coupe was in very original condition and provided the perfect platform to perform our Aldan American coilover suspension handling upgrade. This kit fits 1964-73 Mustang models. Read below for a step-by-step install from this video.

The Aldan American kit includes everything you see here including coilover shocks (front single adjustable shown here), rear smooth body single adjustable shocks, mounting and reinforcement brackets, height adjustment wrench, hardware and complete instructions.

Our stock suspension Mustang sat at 25-inches when measured from the ground to the bottom of the fender lip. As is evident by the large gap between the top of the tire tread to the fender lip, there is plenty of room to safely lower the body height without impacting the body or inner fenderwell.

We used a hydraulic lift to raise and support our Mustang but you can easily perform this upgrade in your driveway using a jack and jack stands. As with any modification where you are lifting the vehicle off the ground, it is important to do so safely using jacks/jack stands that are in good condition.

The classic Mustang front-end suspension is pretty simple with a shock and coil spring fitted above the A-arm. As noted, this suspension design was used by Ford for ten model years, 1964-73.

The type of engine used in your Mustang will also affect the rate of the coilover spring used in the Aldan American kit. Our small block Ford engine (289/302/351Wcid) is pretty much the standard powertrain for these vehicles so we used Aldan American’s 450 lb. per inch rate springs compressing the spring one inch (preload) before installing (total installed height is 9-inches). For Cleveland engines (351Ccid.) and Big block (390 – 427 – 428 cid) engines, a 550 lb. per inch spring is recommended with the same preload as the small block engine application.

Our Mustang’s owner had dressed up his engine bay including chroming the shock tower mounts. Unfortunately for this application, they will not be reused, replaced with Aldan’s cool, black, billet aluminum shock tower mounts.

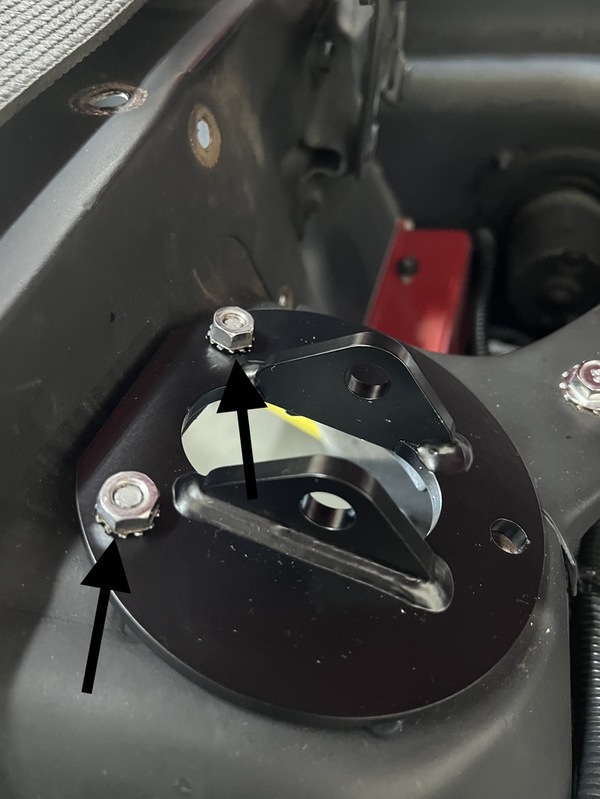

Step one on our upgrade is to remove the inner fender covers to allow access to the coil spring underneath. Eight bolts will need to be removed to release the inner fender panel – six on the inner panel and two on top (arrows).

With the bolts removed, this inner fender panel will drop out allowing full access to the suspension components.

Next we released the top of the shock by removing the upper shock nut. The shock may turn during this procedure so make sure that when you are turning off the nut, you are really removing the nut and not just spinning the shock.

Next, remove the two nuts that hold the bottom of the shock to the spring mount.

To remove the shock, unbolt the mount at the top and slip the assembly out through the top.

To remove the factory coil spring you will need to use a spring compressor. Here we used an internal compressor that is tightened by turning a threaded internal rod that draws the clamps together and compressing the spring.

With the spring out of the way, remove this bolt from the top mount. You can leave the other two bolts in place for now.

Aldan American’s shock tower kit includes the new upper mount (rear) and the reinforcement ring (front). The ring will fit inside the tower to provide important shock tower support.

We positioned the new Aldan American shock tower mount using the two bolts that we left in position. We loosely reinstalling the nuts on the backside bolts (arrows).

The Aldan American kit uses larger bolts for the shock tower than the original factory system. For this reason, these holes will need to be drilled oversize to accept the larger diameter bolts. You can see here that the hole in the new Aldan American mount is larger than the existing hole.

One by one, we opened up each of the holes for the new Aldan American hardware using the top mounting plate as a guide for each new hole. After all three holes had been enlarged, we remove the mount and the bolts.

The Aldan American reinforcement plate fits to the underside of the shock tower using the new oversize bolts. This reinforcement is important for two reasons – Ford Mustang shock towers are notoriously weak and fatigue over time and also to supply added support for the new, stiffer Aldan American coilovers.

020) Mustang

The reinforcement ring is installed from inside the fender. To keep the new Aldan American bolts in place while fitting the ring, we used tape to hold them in place while aligning the bolts through the shock tower holes. For this operation, gravity is not your friend and the bolts will fall out if not taped in place.

The reinforcement ring looks like this prior to the installation of the shock mount.

Aldan American supplies a large number of spacer washers designed to take up the gap between the reinforcement ring and the underside of the shock tower. We needed four washers per bolt to fill this area for our car but you should measure to determine just how many washers you will need to fill this area on your application.

Next we installed the nuts and washers on the topside of the shock mount. When the reinforcement ring is correctly in position, it will look like this.

For those Mustang owners who will be installing an export brace or Monte Carlo bar, the added length of these Aldan American-supplied bolts will allow you to bolt up everything at once without the need for additional hardware. This view is only for the alignment purposes; the bolts must go in from the bottom (with the nuts on top). If the bolts go in from the top, the threaded portion of bolt and fastening bolts could contact the top of the coil over.

In contrast, the top of the shock mount looks like this when finished. Torque these nuts to 35 ft. lbs.

Next we removed the bottom coil spring mount, which was bolted to the Mustang’s upper A-arm. The T-Bar at the bottom of the Aldan American coilover (right) will use the same mount holes but uses the Aldan American hardware, also supplied with the kit.

We inserted the Aldan American coilover from the bottom and attached it to the A-arm with the supplied hardware to mount it up. Note the washer arrangement used to secure the top of the shock and the placement of the coilover rebound adjuster (arrow) that faces towards the outside of the fender.

We set the initial rebound adjustment setting by turning the knob fully counter clockwise (full soft) then back two clicks. In some cases it is hard to reach the rebound adjustment knob so a set of needle nose-pliers can be helpful.

Torque all bolts as noted in the instructions. As a rule, smaller 3/8-inch diameter bolt are torqued to 35 ft. lbs. and larger 1/2-inch bolts to 50 ft. lbs.

When everything is in place and all hardware is fully torqued to spec, the front suspension should look like this.

Moving to the rear of the car, we started with the removal of the shocks with removal of the nuts that hold the shocks to the lower mounts.

The upper shock mounts are accessed through the trunk under small black plastic covers. The nuts that hold the top of the shock are removed with an impact gun here. Note that the top of the shock is angles- matching the angle of the shock within the suspension.

Each end of the Aldan American smooth body shock are fitted with a supplied mount that looks like this (black bracket). This washer slips over this threaded mounting rod and slips into the factory shock mounts. This washer centers the shock in the existing hole in the factory suspension mount.

Of critical importance is aligning the top mount in this position. The bolt that holds the bracket to the shock (arrow) should run parallel to the body of the car, front to back. To do this you will need to use a pry bar, held between the bodywork and the shock mount, to keep it from turning. Note the position of the rebound adjustment knob.

The bottom mount looks like this before tightening. The attachment nut should be torqued to 35 ft. lbs.

Once in place, the smooth body shock will look like this. Make sure that the exhaust or other under body parts don’t contact the shock even when the shock is compressed (such as when the car goes over a bump in the road). Note that the positioning of these parts will change once the car is on the ground so check this by looking under the car and listening for any metal-to-metal contact. If you hear anything, further investigation is needed.

Aldan American suspension height adjustment wrench allows you to lower the Mustang’s body height two inches from factory ride height. The smooth body rear shocks, however, do not allow for this adjustment. As with any suspension change, make sure that tires, wheels and other components do not contact the ground or fenderwell where the car can be unsafe.

Our overall ride height was dropped about one inch from stock in the front at the owner’s request, which helped with handling/cornering and overall appearance.

Need a Different Year?

Ford Mustang Coilover Kits 1979 – 1993

Ford Mustang Lowering Springs 2015 – 2023

Check out our other installs: